Plastic ventilation is mainly intended for places where high corrosion loads do not allow the use of other materials.

It is most commonly used in the chemical industry (production and storage of chemicals) and in sectors,

where air contamination occurs during production processes (galvanizing plants, polishing and etching of glass, hot-dip galvanizing plants, metal pickling and other operations). Furthermore, this air conditioning system can be used in the supply of ventilation and air conditioning equipment.

The advantage of plastic air conditioning is its material resistance, long life and easy installation.

Ventilation conduits are supplied from all types of plastics. We provide complete supplies and installation, including fasteners, hinges, seals. We also supply and install fans, including vibration dampers and electrical connections, as well as equipment for absorbing pollutants contained in the extracted air, working on the principle of absorbing the pollutant by active contact of the air with a suitably selected absorbent.

When realizing ventilation supplies, the optimal solution is always sought and the customer's requirements and needs are followed. Warranty and post-warranty service is a matter of course.

We also offer

Liquid aerosol separators, air filters (absorbers), compensators, muffling inserts and accessories to the above (connecting and anchoring material, gasket seal).

For producing compensators, we use Polystone P Flex material, softened polypropylene or softened PVC.

From project to implementation

Projects are processed in a 3D software (Solidworks app – DWG, STEP format).

We are able to provide project documentation at the level of:

- Study

- Project for building construction

- Copyright controls

When designing ventilation systems, we pay attention to space requirements, design ventilation elements in such a way that the pressure loss has as little impact on the energy balance of the system as possible. This is why we perform calculations for a complete ventilation system (calculations of pressure losses and noise designs). Furthermore, we are able to design warm air heating, for example for pool halls. Heat losses are calculated in the PROTECH software.

Every project is rather very atypical, therefore it is necessary to adjust the materials used and technological processes of production. This makes our company more and more experienced and comprehensive in the industry.

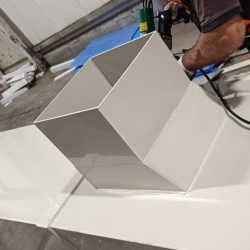

Ventilation system components and design:

- FITTINGS

- Quadrangular bends

- Quadrangular arcs

- Quadrangular symmetrical transitions

- Symmetrical cross-section change

- Digression

- Cross-digression

- STRAIGHT PARTS

- Quadrangular direct piping

- Circular direct piping

- NOISE MUFFLERS

- Circular

- Quadrangular (coulisse)

- DISTRIBUTION ELEMENTS

- Outlets (single row)

- Slots - (single row, multiple rows)

- Diffusers (swirl anemostats, ceiling design, wall design, perforated boxes, plenum boxes)

- END ELEMENTS

- Rainproof blinds

- Exhaust pieces (straight, oblique, atypical design)

- Exhaust heads (circular, rectangular)

- EXTRACTION COVERS (DUCTS)

- Extraction covers (spacious, wall-mounted, atypycal design)

- Extraction channels

- FLOW REGULATORS

- Quadrangular control flap (control type: manual mechanism, with servo drive)

- Circular control flap (control type: manual mechanism, with servo drive)

Material for the production of ventilation:

- polypropylene (PP-H), PPs - not easily flammable material

- polyethylene (PE-HD)

- PE100

- polyvinylidene fluoride (PVDF)

- polyvinyl chloride (PVC-U)